- HOME

- ABOUT US

-

PRODUCTS

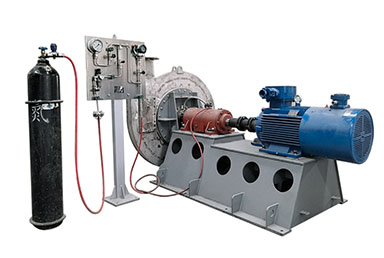

High Pressure Centrifugal Fan Medium Pressure Centrifugal Fan Low Pressure Centrifugal Fan Heavy Duty Centrifugal Fan Customized centrifugal Fan Industrial Furnace Cement Industry Thermal Power Industry Metallurgy Industry Chemical Industry Environmental Protection Industry Glass Industry Variable Stator Blade Axial Flow Fan Mining Fans

- NEWS

- CASES

- SERVICE

- CONTACT US

.jpg)

.jpg)

.jpg)

.jpg)