Which fans are used in the glass industry

Time:Aug 23rd, 2024

Pageviews:22

Share:

Today take you to know which fans are used in the glass industry

Fans play an important role in all production industries. At the center of industries such as glass, food and tobacco, you can find a wide range of industrial fans, each with a specific purpose.

Fans play an important role in all production industries. At the center of industries such as glass, food and tobacco, you can find a wide range of industrial fans, each with a specific purpose.

Glass has a variety of end products, some of which have specific raw materials and therefore unique production processes. However, the industry typically uses fans for combustion, cooling, ambient air cleaning, and fume extraction. When selecting the right equipment for your plant, you first need to understand which step in the production process requires a fan. Then, we must evaluate factors such as required flow and pressure, and system air temperature requirements to select the right fan.

Below are a few of the steps in the glass production process that require a fan:

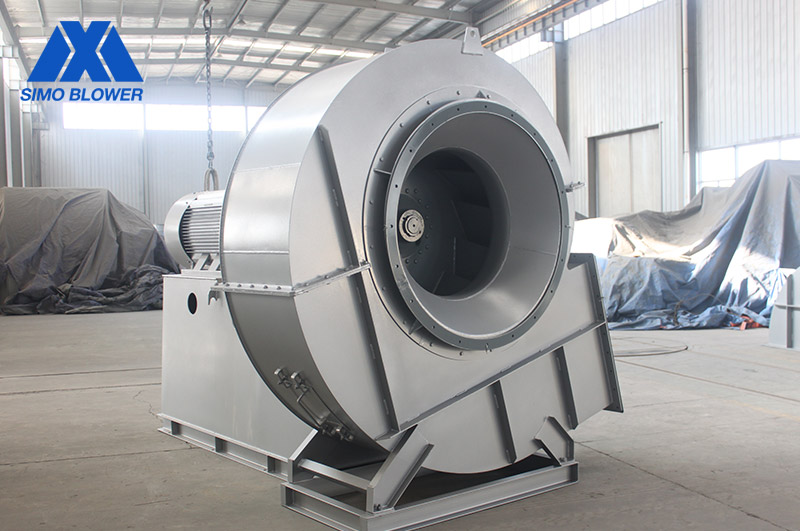

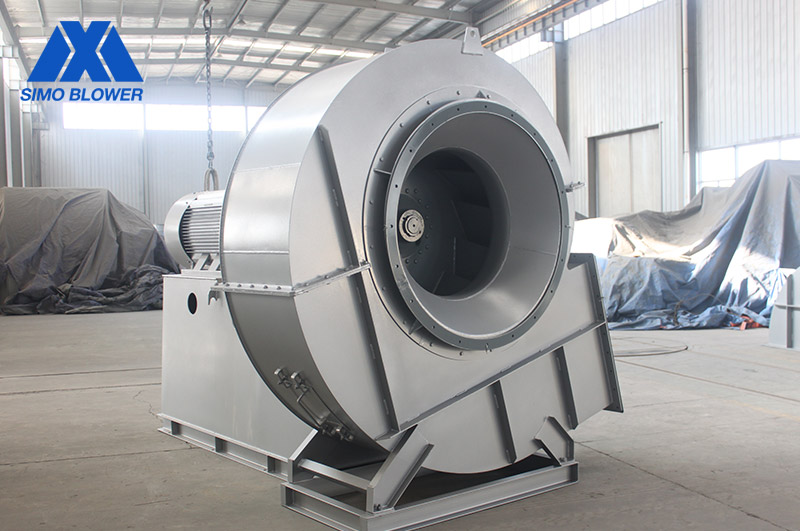

1. Ventilation during glass production: During the glass production process, it is necessary to keep the production plant ventilated to ensure air circulation, which is good for workers' health and productivity. Centrifugal fans and axial fans are commonly used in these ventilation systems.

2. Airflow control during glass melting: During the glass melting process, the temperature and airflow of the molten glass need to be controlled to ensure glass quality and productivity. Blowers play an important role in this process, providing high pressure airflow to maintain the temperature and shape of the molten glass.

Glass Cooling and Quenching: Glass cooling and quenching are critical steps in glass production. Blowers and mixed flow fans are commonly used in these processes to control the cooling rate and temperature distribution of the glass to ensure product quality.

3. Airflow Control in Glass Processing: During glass processing, such as glass cutting and grinding, it is often necessary to utilize fans to remove waste from cutting and provide clean airflow to the work environment.

4. Glass Fume Treatment: The glass industry also requires the treatment of fumes and exhaust gases generated during the melting and production processes. In these flue gas treatment systems, centrifugal fans and mufflers are often used to discharge and treat the exhaust gases.

As described above, centrifugal combustion air, cooling and ventilation fans are therefore predominantly used in plants in the glass manufacturing industry. Since the work involves dealing with high temperatures, manufacturers need fans that can stand up to high temperatures. These fans must also be heavy-duty and abrasion-resistant, as the friction created during the manufacturing process can quickly wear down your machines.

Below are the fans that are essential in the production process:

1. Combustion air fans

As mentioned earlier, raw materials need to be melted in a furnace. For proper combustion, the furnace needs sufficient fuel and oxygen as well as an ignition source. The role of the combustion fan is to provide a steady and continuous airflow to the furnace. The fan draws air into the combustion channel to obtain sufficient airflow for thorough heat transfer. In addition, the correct temperature must be maintained, which the fan does, in order for proper and adequate melting to take place.

2. Cooling fans (for tempering/conditioning and molding)

In order to condition or temper glass and achieve stable molding, the molten material needs to be cooled to a controlled temperature. Industrial fans provide air that circulates over the mold to maintain temperature equalization. This process requires high airflow pressure to remove heat from the material quickly and efficiently.

3. Ventilation and Dust Removal Fans

These fans are vital for glass manufacturing plants, where glass is produced with unwanted dust and fumes, which can be hazardous to the safety of employees. The role of ventilation and dust removal fans is to help you control the dust generated in your workplace, keep your factory clean and take care of your factory workers to achieve good output.

Now that you understand the various types of fans needed for the manufacturing process in the glass industry, you are in a better position to assess the exact type, model, and size needed for your workplace. If you are not sure which model is right for your factory's output, you can always consult an industrial fan manufacturer. Choosing the right fan for your glass manufacturing production will not only result in great output, but will also prove to be durable.

Do you need industrial fans? If so, click here to view our fans. You can also contact us for customized fans.

Previous :