This series of fans meet the needs of roasting, drying, moisture removal and waste heat utilization of various tunnel kilns, rotary kilns, glass kilns, enamel kilns, lime kilns, roller kilns and other kilns. These include the forced air supply and exhaust applications in various production and processing links such as combustion-supporting fans, smoke exhaust fans, circulation fans, ignition cooling fans, and heat circulation fans. Combining rich practical experience and customized fan design, our company has developed several series of high-efficiency combustion-supporting fans with a pressure up to 30kPa, as well as special-structure circulation fans and waste heat fans that can be applied to different furnace types.

APPLICATION

Centrifugal fan is widely used in the cement industry, building materials industry, environmental protection industry, metallurgical industry, power industry projects such as large-scale dust collector, industrial boilers, ventilation systems, cooling.

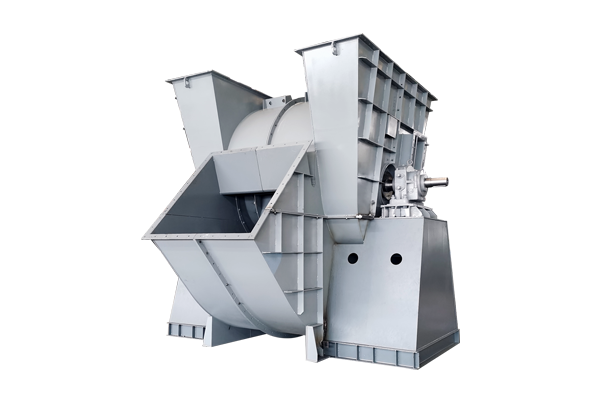

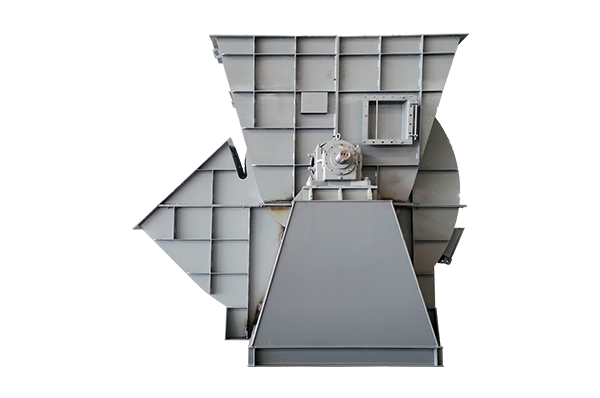

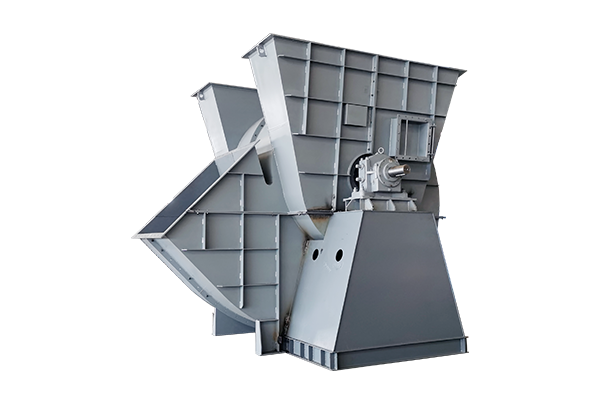

STRUCTURE

Drive, we usually divide the fan into:

In the process of choosing the fan, please select the appropriate fan according to the working conditions.