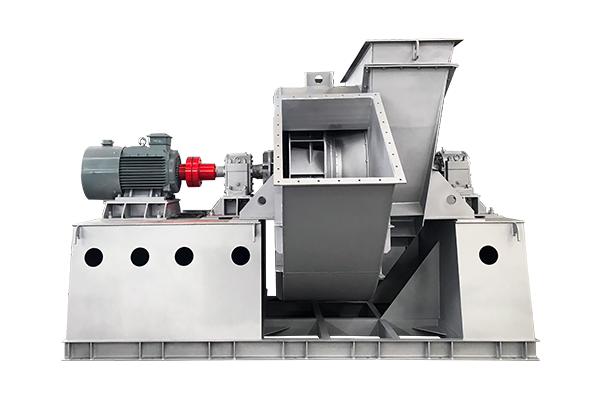

W series high-temperature fans are suitable for transporting weakly corrosive high-temperature gases at 250°C~750°C. It is mostly used for flue gas exhaust of heating furnace, high temperature dust gas exhaust of cement production line and other high temperature gas conveying systems. It mainly includes W4-73, W5-55, W6-29, W6-31, W6-39, W7-16, W7-28 and other series of high temperature fans. This series of fans has the characteristics of strong anti-deformation ability, stable operation, easy installation and maintenance, etc. Fan aerodynamic parameters, layout structure, direction of rotation and angle can be designed and manufactured according to user requirements.

Product features:

1. The blower adopts a thermal expansion structure design to eliminate the effects of high-temperature thermal expansion.

Its working principle is that the thermal expansion mechanism controls the direction of movement of the casing in both cold and hot states, while the elastic bolts ensure that the support legs can move smoothly on the foundation after the casing expands when heated, and return smoothly to their original position when cold. This avoids affecting the concrete foundation and causing plastic deformation of the blower. The foundation is not affected by any thermal expansion, thus protecting both the blower and the foundation.

2. Determination of the clearance between the air inlet and the impeller inlet.

The clearance between the air inlet and the impeller inlet in both cold and hot states is calculated and determined, and a reasonable allowance is made to ensure the safe and reliable operation of the blower in both cold and hot states.

3. Impeller and main shaft fit tolerance.

When the impeller expands at high temperatures, the expansion of the hub shaft hole is much greater than the expansion of the shaft. At this time, the interference fit in the cold state is easily broken, causing blower vibration or shortening the rotor's service life. Therefore, interference fit calculations, selection of thermal fitting parameters, and selection of impeller and main shaft fit tolerances are crucial and must be rationally chosen to ensure the safe and reliable operation of the fan.

4. Seal between shaft and casing

The design of the seal between the main shaft and casing must consider a floating combination seal that is resistant to high temperatures and does not move with casing expansion.

Dive Mode

Drive, we usually divide the fan into:

In the process of choosing the fan, please select the appropriate fan according to the working conditions.

Application Scenarios

.png)