.jpg)

.jpg)

.jpg)

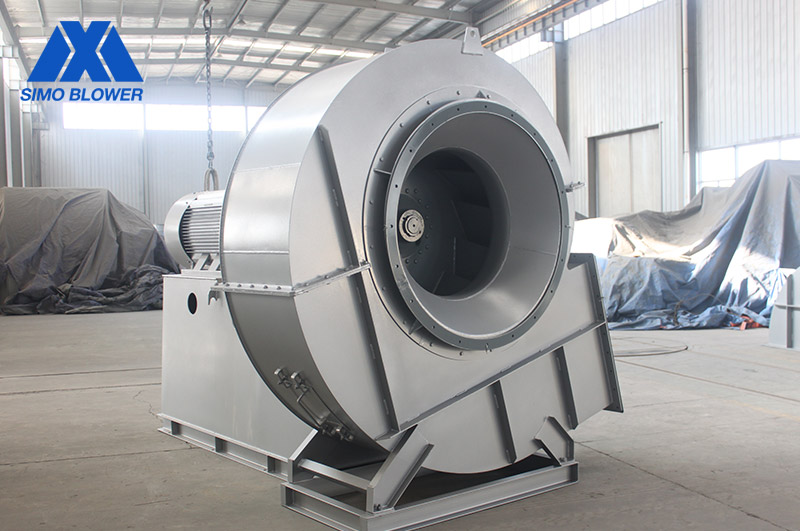

Xinxiang SIMO Blower Co., Ltd., formerly known as Xinxiang Blower Factory, was established in 1955, which is the designated factory for fan production by the former Ministry of Machinery Industry.

In May 2018, the national SME share transfer system was listed. It is one of the larger fan manufacturers in central China and a member unit of China Fan Association.